Paper-based technology

Practical Action

Stage 1: Building the chair

Add to your working kit:

A hole-cutting tool (such as a flattened five-inch nail and stone hammer); a piercing tool (a

smaller sharpened nail in a holder); a piece of rusty piping (to use as a rasp); and some string.

You need to know:

How to layer paper or thin card. Pieces of paper are pasted (and thus stretched) and

applied with hand pressure to an article. They must lie quite flat and may have to be

lifted, torn, and relaid. They may be applied one, two, or three layers thick, and may be

referred to as ―strapping‖, ―binding‖, ―strengthening‖, or ―tidying‖, according to the job they

do.

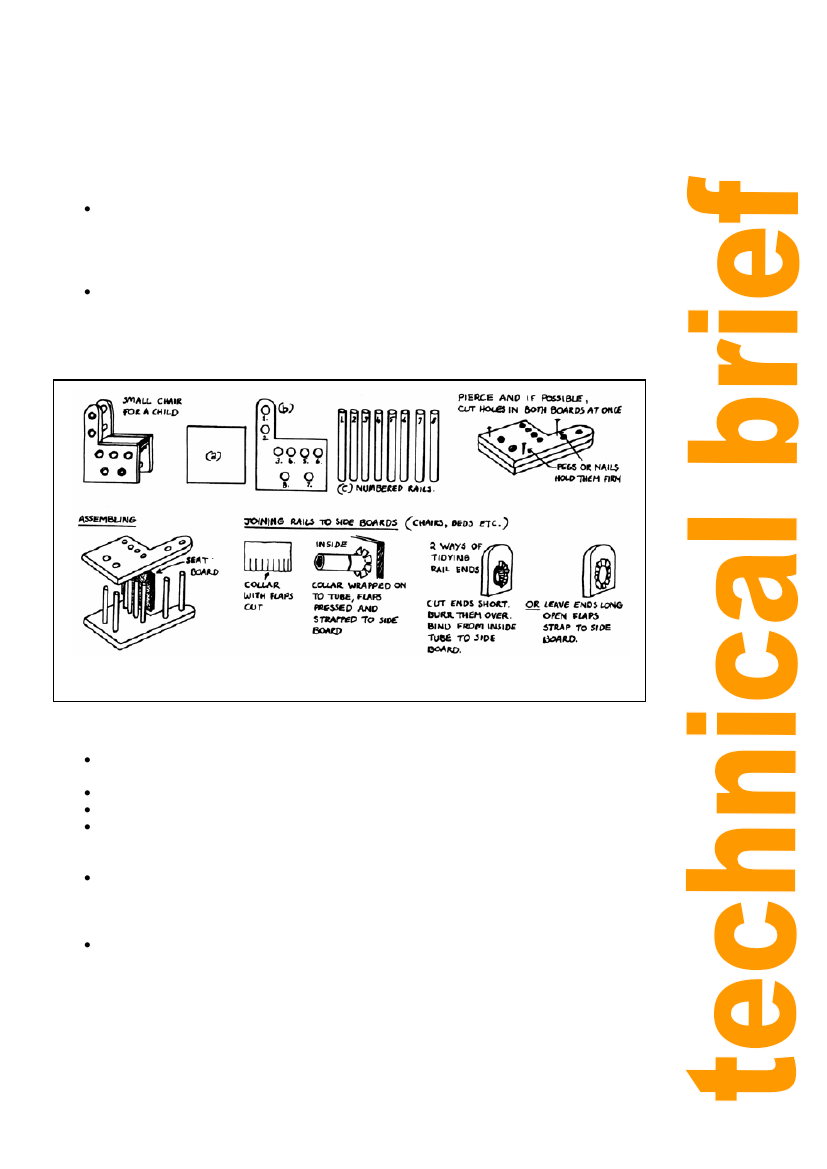

How to cut holes for tubes. Holes can be rough but must hold the tube tightly without

crushing it. Their sides should be perpendicular. Use a chisel-like tool to cut them.

Enlarge or tidy them with the piece of piping. Match each hole to its tube and number

them both.

Figure 3: A railed chair - Utility approach two

Get to work:

Tidy all board edges and make the two sideboards identical by rubbing on a concrete

surface, with or without paste. Bind the edges.

Cut the holes. Test-fit and number the tubes.

Do a mock assembly (i.e. without paste).

Lay one sideboard on the table and fit the tubes into their holes. Hold the other sideboard

in position over the tubes and guide, press, and screw each tube into its hole. Place the

seatboard in position then press the sideboard hard down against the seatboard.

Stand the chair upright and manipulate the rails so that their ends project evenly about

5mm through one sideboard. (Trim the other ends later on.) Square up everything,

checking particularly that the distance between the sideboards is everywhere the same

and that the chair stands upright, then disassemble the chair.

Paste all joining pieces, rail ends, and holes, and reassemble the chair. Pierce holes

through the seatboard and tie it firmly down to at least one rail. Trim the remaining rail-

ends to project 3 to 5mm. Burr all rail ends over with a suitably shaped stone, cutting

into them if necessary. They should lie flat like rivets. Stand the chair up, and after

squaring up leave it to dry with a weighted board across the seat.

Stage 2: Strengthening and tidying

First: Add some magazine paper to your working space.

5